When we assumed responsibility for

Eolian way back in 1997, she had covers for the hatches, but they were solid canvas, making it very dark down below - not an ideal situation for a liveaboard. So we put some clear vinyl into the covers, first stitching it around the perimeter, and then cutting away the canvas that covered the vinyl. In this way, the shape of the original cover was preserved. When cutting away the opening, we left a 1/2" allowance which we folded under and stitched down with a second row of stitches.

But the best vinyl we had available to us in Seattle was not the good stuff, and it clouded over in 7 or 8 years, necessitating a replacement.

Which we did. Again. With the same crummy vinyl.

Now here we are again. But this time the problem is bigger. In addition to the failed vinyl, now the stitching is rotten and the Sunbrella has shrunken up. But, in the intervening years, I have learned a few things.

|

| Always 100% cloudy down below |

|

| Stitching is rotten too... |

So now it is time for a full fresh start. And this time, I am using Strataglass, the top of the line vinyl ($216 for a 54"x110" sheet, and worth every single penny of that.). It is a three-part lamination, with fluoropolymer outer layers that prevent migration and loss of the plasticizers which make vinyl pliable (without the plasticizers, vinyl is hard... records are made from unplasticized vinyl). The fluoropolymer layers also greatly reduce UV degradation.

Some design work was needed...

- What is the size of the hatch?

- How big should the vinyl cutout be?

- How long should the skirt be?

- How big should the bottom hem be (it should be wide enough so the snaps pass thru at least a double layer of fabric)?

- How big should the fold back hem at the vinyl be?

- And finally, where should the seams be located? This is important to limit the fabric thicknesses to be sewn thru.

I didn't want to make the cover from a big piece of fabric and then cut out the center (following the process that got us here via the original covers), because that would be a huge waste of Sunbrella. So I cut 4 strips of fabric that satisfied the design criteria above, hemmed them, and stitched them together, making an open square. (Note that I am using Tenara teflon thread -

no polyester thread is suitable for outdoor service. Polyester thread will last about 5 years outside in the sun; Tenara has a lifetime guarantee.)

It was a little tricky attaching the floppy open square to the vinyl - judicious use of basting tape saved the day. As a secondary benefit, the basting tape sealed the vinyl to the fabric, making a water-resistant (waterproof?) joint between vinyl and fabric.

|

| Now we need corners |

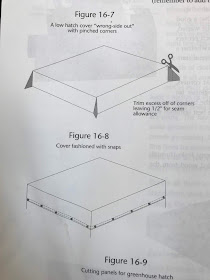

Now to make the corners... I used the procedure outlined in Jim Grant's book below. Wrong side up, you place the square over the hatch and crease the corners. Mark the end points of the creases, which should be the actual outside corners of the hatch, plus a little wiggle room. Stitch up the corners at a 45° angle from the crease. In the illustration below, Jim suggested cutting off the triangles; I just stitched them to the sides.

At this point I should make yet another recommendation for

Sailrite. All my canvas work supplies come from them (including my sewing machine!), and they are constantly giving back to the community with hundreds of how-to videos and tutorials. In fact, this book was written by Jim Grant, who I assume to be part of the Sailrite operation which was created by the Grant family way back in 1969.

|

| Ta Da! |

Now to get the full advantage of the new, clear vinyl, I have to clean the plexiglass on the hatch itself - it is dirty and water stained from the rain, etc. that the failed cover let in.